My name is Louise, I'm from the UK and I am writing this blog to show people my cage building experience so that I can hopefully help others to build their own cages and provide some inspiration. Degus require a lot of running space and therefore a large enclosure is a necessity. I hope to show that a large cage build can be completed by someone who really has no proper DIY skills but has the willingness to provide a good home for their degus. Unfortunately I, like a lot of new degu owners, was given poor advice on how to house these wonderful little animals by the pet shop (for me it was pets at home) and as a result bought a cage that was far too small to start with.

I bought my first two degus Millie & Peach in April 2013, I'll admit I should have done more research before buying them and I knew little about their housing needs.

Here is one of the first photos I ever took of them.

The first cage I ever used was a 3 tier wire ferret cage which I added wooden levels to so as not to hurt their feet.

I did a lot of research online and realised the cage was far too small and set about designing a larger cage.

A great website with loads of degu information is:

Degus International Community

This

forum is full of knowledgeable, experienced degu owners who are willing

to offer advice and help to everyone, degu welfare is their top

priority.

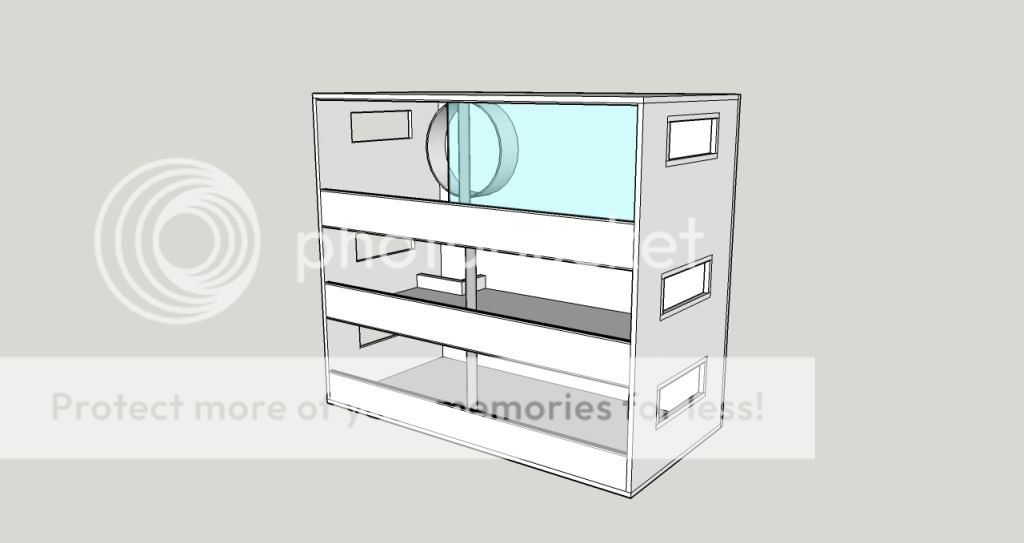

My first cage build turned out like this.

This cage was made from large plywood boards that I bought from B&Q and everything accessible in the cage made from kiln dried pine. Total CARA (cumulative available running area) was 15,600cm

2

View CARA chart

One evening in January 2014 I went to pets at home to buy some more sawdust and ended up buying two more little degu girls, Morpheus and Sky. I quickly extended the cage by adding a top section and extending all the levels to be full width levels. Total CARA is 36,600cm2.

|

| Left to Right - Morpheus, Peach, Sky & Millie |

|

For a few months the four girls lived happily as a group but once Morpheus and Sky hit puberty things started to go downhill. They started fighting very badly, ripping out tufts of fur and drawing blood from each other so we separated the pairs giving them both 3 levels in the cage with a wire mesh vertical divider in the middle so they could still see each other. We tried for ages to get them back together and although introductions went well outside the cage as soon as they got back into the cage (even with a mesh divider) they became aggressive and it caused the two pairs to start fighting amongst themselves too. We have now decided that -at least for the next year or so- we are going to keep them in pairs to reduce the stress amongst them.

Problems

I wanted to post a few photos of some of the problems I have had along the way with the old cages so anyone planning their own cage can be aware of these issues before they build there own.

Degus will chew everything

Don't use plastic bottles inside the cage as they will chew them and not only is it dangerous for their health, once a hole has been made there will be no vacuum and the water will spill out all over the cage soaking the bedding.

I also used little wooden water bottle holders which I just slotted the water bottles into, as you can see these were also chewed.

At first I used kiln dried pine strips of wood along the front of every

level to stop the sawdust falling off the ledges but soon discovered

that they will just chew on these until they are none existent. However a good, cheap product I found to prevent this problem is

Galvanised Steel Angle Bead you can just lay this along the tops of all exposed edges to protect them from being destroyed.

As you can see from the photos a major problem I faced was wood

shavings being caught between my sliding acrylic doors and the wood I

had placed behind to try and stop the shavings falling out. This has

caused so much annoyance and so much hoovering in my house because not

only does it fall in front of the cage it is very easily stepped in and

then it just ends up absolutely everywhere.

On one

level I tried to remove the back piece of wood which measured 10cm high

and just put a metal lip behind the acrylic to try to stop them chewing

the plastic runners but the doors were only sitting on a piece of wood

that was 5cm high - this is not enough. After extending my levels the problem got much worse because it was getting trapped between the levels and the doors.

Sliding doors

I absolutely love having sliding doors in the enclosure it looks so professional and you can easily see your degus and they are great when it comes to cleaning because you can just lift them out. A problem I found with them however is that in my enclosure the levels were 120cm long and made of heavy plywood which has drooped in the center over time. Because of this it is now resting on the doors which makes it incredibly hard to open a few of them and lifting them out now for cleaning is a nightmare. For anyone using sliding doors I would recommend using some sort of support in the center of the levels.

I find a lot of sites online only show photos of brand new cages that have not yet been lived in so it's hard to foresee any problems, hopefully these photos will help you not make the same mistakes I did!